END USER

The end user is the individual who will use, handle or have direct access to a given good, which is the result of a production process.

The end user is the individual who will use, handle or have direct access to a given good, which is the result of a production process.

Companies specialising in the management of materials from waste collection. They provide specific facilities for the transport, sorting and treatment of recyclable materials, separate collection, multi-material, municipal and industrial waste. The successful treatment of waste fractions is mainly linked to the sorting that is carried out at source by the end user.

Sequence of commercial intermediaries (companies or private individuals) who provide the passage of goods from the producer to the final purchaser. This passage takes place through distribution channels, which make products available at the times, places and in the manner desired by consumers.

Source:

Inspired by Glossary Marketing, “Distribution Channels”: www.glossariomarketing.it

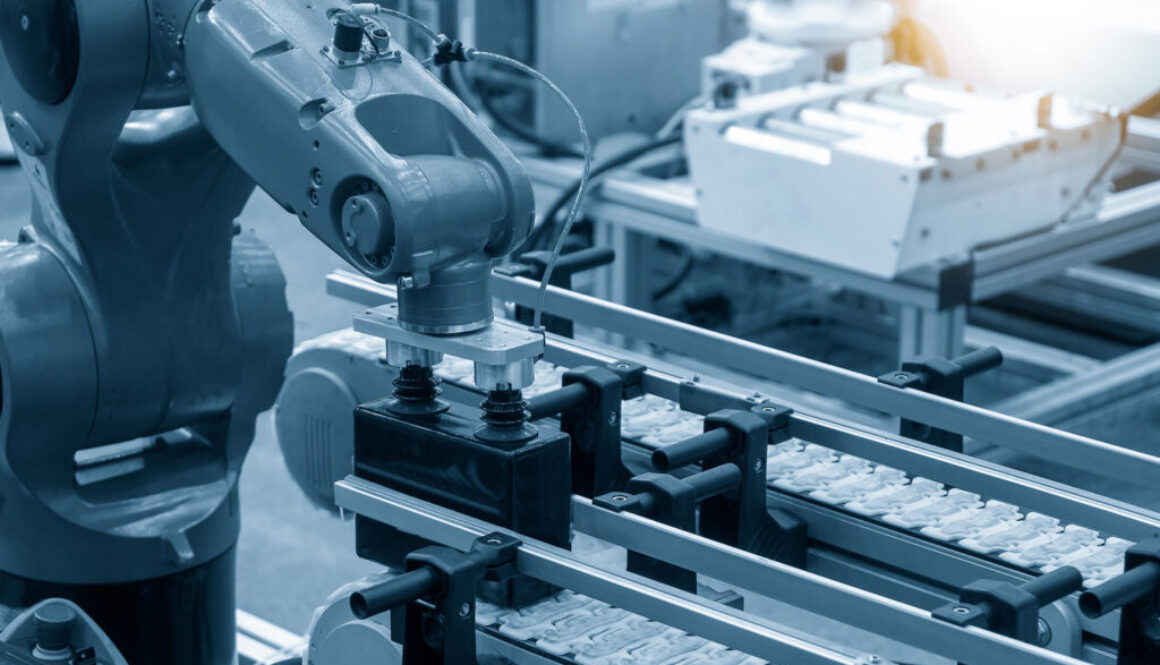

Those who, through simple or complex operations, produce a good by transforming other goods. Production systems have undergone a transformation stimulated on the one hand by the spread of new information and communication technologies, and on the other by the globalization of markets. Today we are moving towards highly articulated network structures, with a high capacity to adapt to rapidly changing situations, significant internal flexibility, the ability to appropriately manage the complexity of the environment, the tasks that have to be performed and the new technologies that are able to support and facilitate the execution of these tasks.

Source:

Inspired by Treccani, “Production”: www.treccani.it

Packaging machinery automates the process of forming the packaging, in relation to the product it is to contain, with the aim of making it faster, therefore more economical, increasing the company’s productivity. In each sector, then, packaging responds to specific needs: from the need to preserve the contents intact, to the need to avoid external contamination from production to consumption of the product itself. For example, the packaging of food products responds both to the need to keep the product intact, and to keep it in safe hygienic conditions. It is precisely in relation to the function that the packaging must fulfil that the automatic machine is designed: for example, packaging machines for food products, including beverages, must allow a packaging process that guarantees adequate hygiene standards.

Source:

CMS Group, “What is packaging machinery?”, tratto da: www.gruppocms.com

Company specialising in film converting processes such as forming, orienting, metallising, laminating, coating, printing, winding and slitting.

Source:

Morris, B. A. ‘Converting Processes. In Morris, B. A. (Edited by) “The Science and Technology of Flexible Packaging. Multilayer Films from Resin and Process to End Use” (2017), William Andrew Publishing, Norwich. (ENG) ISBN 97803242738.

These are those who operate the transformation process, i.e. they transform raw materials, e.g. in the form of polymer pellets, with steps that may include the formation and orientation of the film, until a final packaging structure is obtained.

Source:

Morris, B. A. ‘Converting Processes. In Morris, B. A. (Edited by) “The Science and Technology of Flexible Packaging. Multilayer Films from Resin and Process to End Use” (2017), William Andrew Publishing, Norwich. (ENG) ISBN 97803242738.

Individuals or groups that can influence or are influenced by the achievement of an organisation’s or company’s objective, and individuals influenced by the use of specific resources, although not directly involved.

Source:

Mazzei, A., Ravazzani, S., “Dialogue with Stakeholders. Listening and intercultural sensitivity for public relations and corporate communication” (2012), FrancoAngeli s.r.l., Milan. ISBN 9788891704146, 8891704148.

Welding is a process of joining two flaps of film, usually plastic, through the use of tools.

New frontiers are looking at cold sealing which reduces the amount of waste due to the gentleness of the system on the contained product, such as chocolate bars, even during machine downtime. In addition, the use of problematic cold sealing adhesives can be avoided. For this technology, the ultrasonic generator allows monitoring of the quality of the pouch seam: hermetic sealing is guaranteed even if there is product in the seam area that is normally contained in the package (defined as ‘contamination’).

Source:

Herrmannultraschall, “Ultrasonic sealing technology“, updated 08-07-2020, taken from: https://static.herrmannultraschall.com/fileadmin/user_upload/Donwloads/FOOD_ITA.pdf

Scientific and objective procedure for assessing the energy and environmental loads related to the analyzed system, carried out through the identification of energy resources, materials used and waste released into the environment throughout the product’s life cycle in a “cradle-to-cradle” perspective. The LCA methodology finds its origins in the 1970s as a development of energy analysis, where purely energy-related variables are integrated with typically environmental ones. Energy variables are integrated with typically environmental ones throughout the entire life cycle. Currently, ISO 14040 and 14044 represent the international standard to which every analyst refers to and, if necessary, have each LCA study verified.

Source:

CONAI (Consorzio Nazionale Imballaggi), “Guidelines for the facilitation of plastic packaging recycling activities“, updated 20-12-2018, taken from: www.progettarericiclo.com